MINRO STIR PRO Nozzles - Coreless Gas Purging

MINRO STIR PRO NOZZLES bring the advantages of inert gas stirring of molten metals to the coreless induction furnace and foundries.

Customer experiences (ferrous and non-ferrous foundry):

- Decreased dissolved gases in the metal

- Increased cleanliness and fluidity

- Improved metal density and alloy recovery

- Decreased scrap castings

- Less grinding required during finishing process

- Reduced oxidation of molten metal bath in an air-melt application by providing a “blanket” of inert gas on top during bubbling

- Multiple campaign use per nozzle

- Suited for both ferrous and non-ferrous foundries

Available in various types and sizes to fit a range of coreless furnaces, and designed for multiple campaign use.

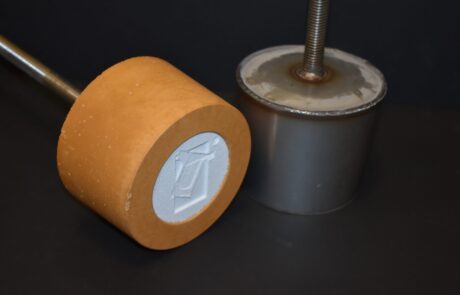

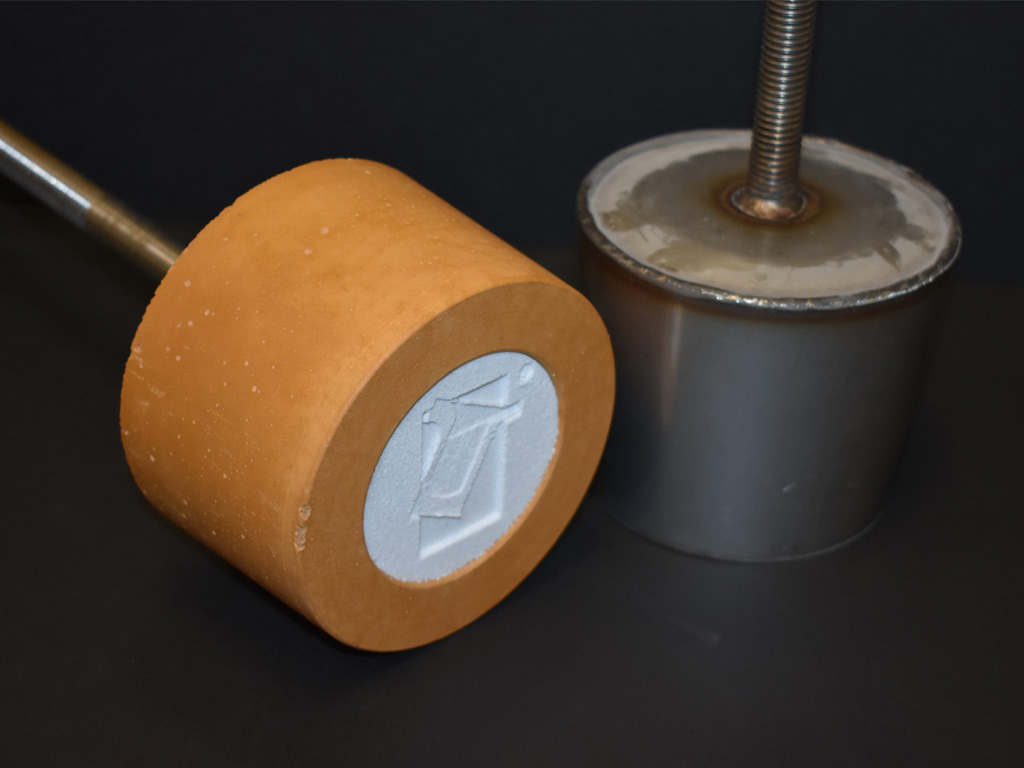

MATERIAL DETAILS

- SHROUDED STANDARD NOZZLE – durable stainless steel retainment can design

- SHROUDED MINI NOZZLE – durable stainless steel retainment can, features small cross section, for 500 lb or smaller furnace

- CAST NOZZLE – a fully ceramic design for high temperature applications or where magnetic coupling may be present