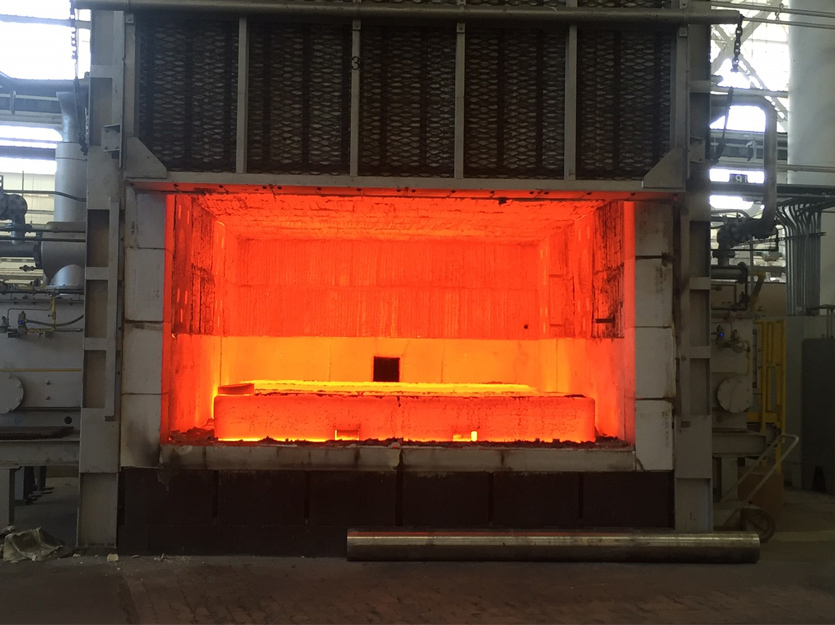

Castables for Heat Treat & Forge

Castables for Heat Treat & Forge

Allied produces multiple grades of dense and lightweight castable refractories for the heat treating and forging market. This includes various conventional and low-cement castables, phosphoric acid patching products, and colloidal silica-bonded castables. Unique castable products are designed for use in areas of high abrasion and thermal shock.

MATERIAL DETAILS

| Product | Al2O3% | Density (g/cm3 / lb/ft3) |

Temperature Limit (°C / °F) |

|---|---|---|---|

| CAST 217 FS - FS FINE | 20.5 | 1.81 / 113 | 1315 / 2400 |

| COIL CAST 97A | 96.6 | 3.03 / 189 | 1650 / 3000 |

| COIL CAST FS - FS FAST | 27.5 | 2.03 / 127 | 1315 / 2400 |

| COIL CAST M | 66.3 | 2.37 / 148 | 1650 / 3000 |

| TUFFLOOR® | 35.1 | 2.11 / 132 | 650 / 1200 |

| TUFFLOOR® HT | 45.3 | 2.08 / 130 | 1370 / 2500 |

| Product | Al2O3% | Density (g/cm3 / lb/ft3) |

Temperature Limit (°C / °F) |

|---|---|---|---|

| TUFFLOOR® | 35.1 | 2.11 / 132 | 650 / 1200 |

| TUFF-FLO FSM | 34.8 | 2.20 / 137 | 1370 / 2500 |

| PUMPLITE 80 | 41.6 | 1.25 / 85 | 1425 / 2600 |

| ARMORMAX® 70 SR | 70.1 | 2.66 / 166 | 1430 / 2600 |

| TUFF-FLO 47 | 46.7 | 2.26 / 141 (Vibration Cast) 2.23 / 139 (Pumping) |

1540 / 2800 |

| ALAKAST™ 65- LC-P | 64.7 | 2.40 / 150.2 | 1649 / 3000 |

| TUFF-FLO 50 | 50.2 | 2.32 / 145 | 1650 / 3000 |

| TUFF-FLO 60 A | 59.6 | 2.58 / 161 | 1700 / 3100 |

| Product | Al2O3% | Density (g/cm3 / lb/ft3) |

Temperature Limit (°C / °F) |

|---|---|---|---|

| BLASTKAST 70 LC | 65.3 | 2.36 / 147.6 | 1649 / 3000 |

| TUFFCRETE® 70X | 68.0 | 2.63 / 164 | 1650 / 3000 |

| FAST-TURN 60 M | 60.5 | 2.48 / 155 | 1700 / 3100 |

| Product | Al2O3% | Density (g/cm3 / lb/ft3) |

Temperature Limit (°C / °F) |

|---|---|---|---|

| INSULMIX® 2025 | 15.4 | 0.32 - 0.48 / 20 - 30 | 1090 / 2500 |

| INSULMIX® 2460 LI | 43.8 | 1.00 / 62 | 1315 / 2400 |

| INSULMIX® 25 HS | 29.0 | 1.47 / 92 | 1370 / 2500 |