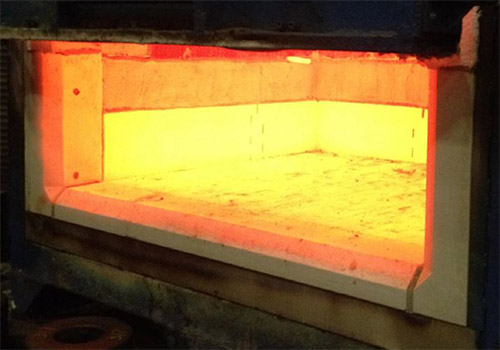

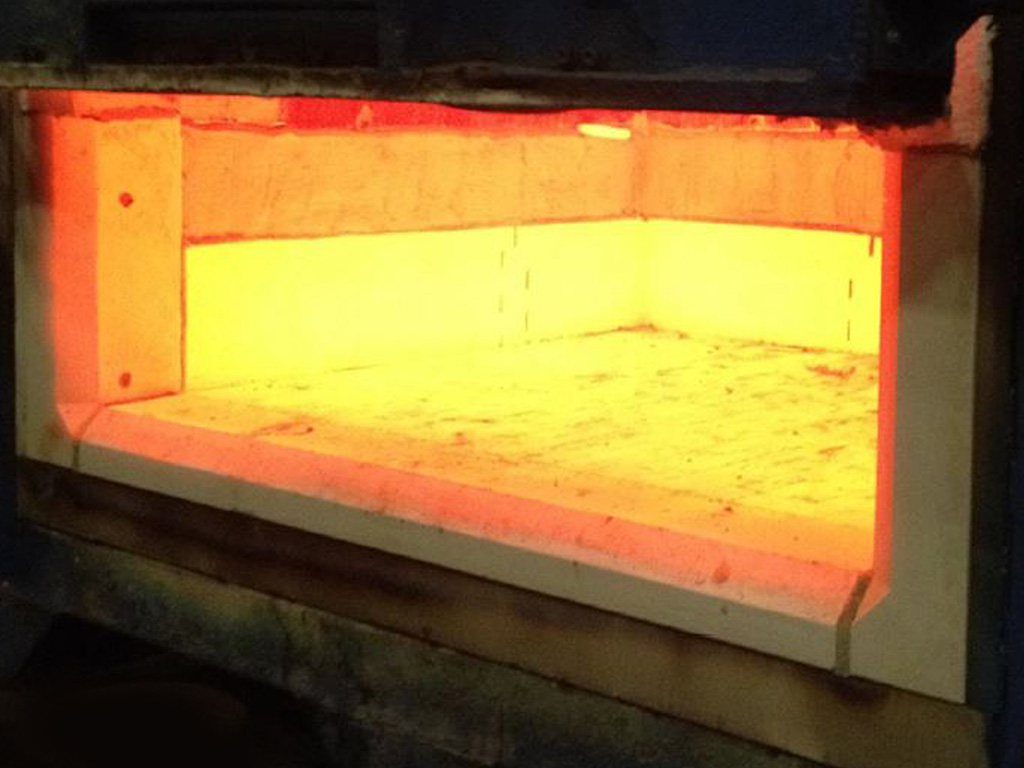

ARMORMAX®

ARMORMAX® can withstand repeated thermal cycling, mechanical impact and abrasion due to its high reinforcing needle content.

The metal fibers are pre-blended and uniformly distributed in the refractory matrix.

Benefits:

- High fracture toughness when thermally cycled

- Low abrasion loss

- High mechanical impact resistance

- Well suited for applications up to 1200°C (2200°F) continuous exposure

- Characterized for low water requirements (ranging from 4.5% to 6.5% by weight)

- All versions are low-cement castables

- Excellent flowability for high wire-containing refractory ceramic castables